.

.

ZZZZZZZZZZZZZZZZZZZZZZZZZZZZ…. Huh….. What…..

Well, not much been going on here for a while, and with me too. I took a break from slot car silliness myself for over a year. During that so-called break I was still doodling away…

In my last installments in the design progression series (ignoring the throwback 1236-Cc2), I had built the 0.032” wire framed 1229-Cc3 and 1233-Cc3. I was going to make the next build, the 1235, when the tracks in west Floridada closed and a fair dose of apathy set in. About this same time I started the aforementioned doodles titled “1237”.

There was a long run of chassis, built or not, that had started with the framing pattern established with the 1219 and continued up through the 1235. I was aware that at this point this framing pattern had largely run its course. A lot of chassis component structures had been tested, along with the comparisons of 0.047” wire framed chassis with 0.039” chassis and eventually 0.032” chassis.

But the original “1237” doodle was a departure from the “1219”. Over time during the last year or so the first doodles became more doodles, then detailed drawings and notes, then some revisions, followed by more drawings and notations, as well as morphing into more designs, the 1238, the 1239, the 1240…

The “What”:

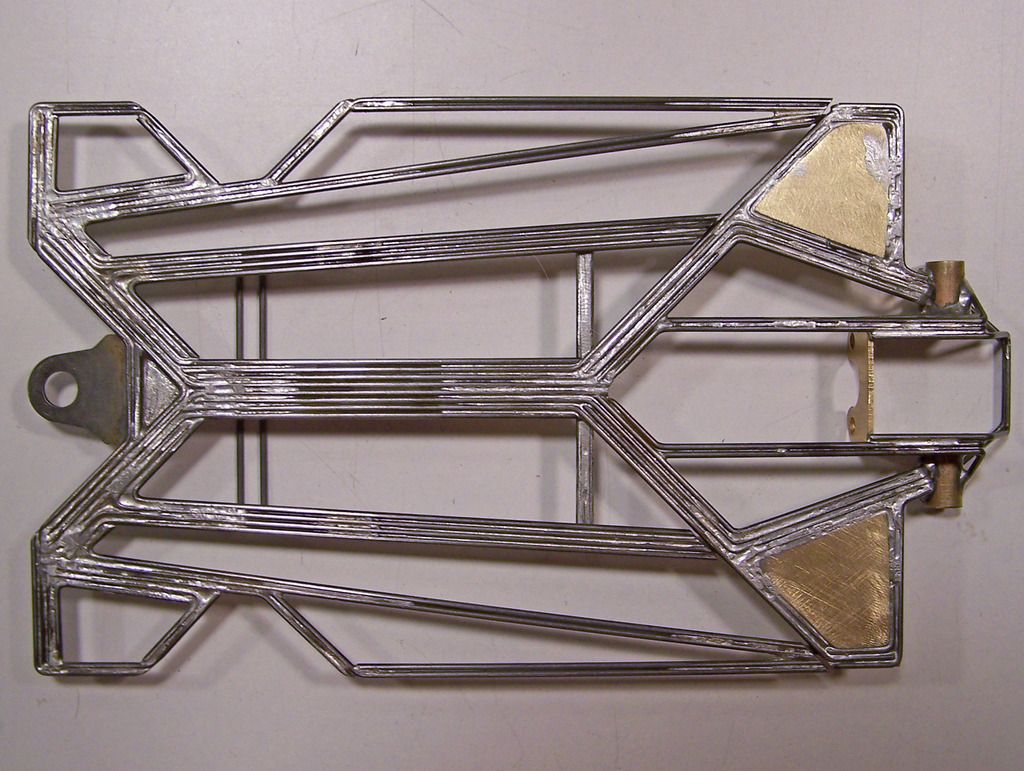

The 1237 framing pattern uses the same rear structure devised for the 1229’s (motor box, rear axle support, and flanking static pans), but from there it all changes. The main rail (instead of the typical two on either side) is a single structure running from the forward “point” of the rear assembly, up the center of the chassis, to the guide mount assembly. From the guide assembly the front structure, including the front wings, spreads to both sides. From the front assembly there are two sets of structures extending rearward: 1) lateral side “pans”, including the front wheel wells, extending to and loosely articulating (0.055” wire in 1/8” square brass tube) with the flanking static pans on the rear assembly; 2) rail structures, medial on each side between the side pans and the center main rail structures, extending to and more tightly articulating (0.055” wire in 3/32” round brass tube) with the rear assembly, which on my drawings became noted as “buttress rails”, and I will refer to them as such through the rest of this description.

The “Why”:

This basic framing pattern of the 1237 accomplished a few conceptual ideas.

The initial idea was to get rid of a lot of “clutter” that had accumulated on the 1219-based chassis. These things were becoming some real chunky-monkeys, and the 1233’s, though functionally spot-on, are wickedly complex structurally. A new base framing pattern was overdue.

On the 1219-based 1233 frames the center-guide section, the indirect main rails, the front axle rails, and the harmonic pan rails all extended from the rear chassis assembly; that’s a lot of stuff. The idea was to get the indirect main rails and the front axle rails off of the rear assembly.

What came of this was the original 1237 doodle (literally). To open up the interior of the chassis framing, the two main rail structures were replaced by a centralized singular main rail structure; the side pans were adaptations of the ones I used on the 1233’s which had worked so well. This left a lot of open area in the middle of the design. Thinking it looked rather spindly, as a whim I drew in the “buttress rails” and noted they should articulate with, and not attach directly to, the rear of the chassis (if they attach directly they just become main rails). That’s when “the light” came on. While it would take revisions to determine the exact location of the connections of the side pans and buttress rails to the front assembly, the basic design remained.

Almost immediately the design progression became clear:

1237: Additional incorporation of an adjustable “bite bar” mounted to the center main rail / guide mount structure extending to the buttress rails.

1238: 1237 with incorporation of indirect main rails (IMR).

Commonly these are called “z-rails”, but in this case are “v-rails”. The central main rail of the 1238 extends from the rear assembly only to the guide tongue structure (CG structure). The first component rail of the IMR’s attach to both sides of the front sides of the CG and extend parallel/rearwards; the second IMR component rails attach to the rear of the first IMR rails, extending parallel/forwards to attach to the front assembly (front spanning wire and front wing assemblies).

1239: 1238 with incorporation of front axle rails (FAR) and their variable spring wire (VSW) adjustors.

The left and right FAR’s each consist of two sets of rails flanking both sides and attaching at the rear of the buttress rails. Each has its own VSW adjustment, the VSW tubes with adjusting screw attaching atop the buttress rails. On the 1219-based frames there was only a single VSW adjustor for the front axle, effecting both sides equally; this new 1237-based design will allow separate left and right adjustments.

1240: 1239 with incorporation of harmonic pan rails.

These will (still; I’ll tell you later) extend from the rear assembly forward in between the buttress/FAR’s and the CG/IMR’s.

The “How”:

Finally, and just recently, I decided I just had to build the 1237 as a proof of concept, and to have a structure in my hands to look at and analyze.

The first attempt would be a -Cc2 version; inline ret-ro, WB 3.875”, RAX-GPC 4.875”, GL 1.00”, built using 0.039” wire.

The immediate next build would be an “identical” -Cc3 version built using 0.032” wire. I could set up both and compare as needed.

First thing I happily noticed, the 1237 frame is easier and quicker to build than the 1219-based frames. That was another intended consequence of the new design.

And before I even finished it…

The “Now What”:

Holding the nearly completed 1237-Cc2 chassis, some things became apparent:

1) I really like it. Completely subjective, but gratifying nonetheless.

2) No need to build a 0.032” -Cc3 version of the 1237 to compare to this 0.039” frame I’d just built. I could already “see” exactly how it would be “different”. And I also knew from previous comparisons of 0.039” wire frames and 0.032” wire frames (1229-Cc2 vs 1229-Cc3, and 1233-Cc2 vs 1233-Cc3) that the 0.032” versions were an improvement. So anything further in this design/build sequence will be 0.032” wire framed.

3) There is little reason to even finish building this 1237-Cc2. Okay, all it needs is body mounting pin tubes. And I’m thinking I could even add some loose-mounted pans between the CG main rail and the buttress rails. Okay, maybe. But that would use up another front axle, set of fronts, guide, lead wires, motor, gears, bearings, axle, tires, painted body… Sure I can scrap all that off, but why even make the effort and take the time for a car I plan to obsolete almost immediately, especially if…

4) …if there was no reason now to build the 1238, and I could go straight to the 1239. The 1238 was an intermediate feasibility design only. Now that I can visualize how easily the 1238 can be built, it’s a no-brainer to move right on to the 1239 build, in 0.032” wire too. (Not so with the 1239 to 1240 jump, where spacing and balance becomes more of a consideration).

You know, this hobby just might be fun…

Rick / CMF3

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

As they say at an accident scene, “Nothing to see here. Move along.”

Last edited by CMF3; 12-16-2015 at 06:46 AM.

Okay, I changed my mind back to my original plan. This was largely due to my recalling all the times I would skip steps in any design/build progression only to have to back-track afterwards. You’d think I’d know better by now, but obviously I’m dealing with some intrinsic flaw in the old mental processes. Besides, the more I played with the uncompleted chassis contemplating the next build, the more I liked it and wanted to finish it.

By this time I had replaced my supply of 1/16” brass tube, so I put on the raised (atop 0.039” wire) body mount pin tubes (still using the “six-pin technology”).

I also concluded the mass of the RTR car would be under 100 grams (that number thing I love so much). I had originally considered placing two pans (0.010” brass sheet backed along the perimeter with 0.032” wire) one each between the central main rail and the two buttress rails; these would be dynamic pans, loosely hinged (0.032” wire in 1/16” / 0.006”-wall brass tube), so as not to interfere with the movement of the adjacent structures; some fore-aft movement in these pans was also allowed. So I did. All done they added about 5.8 grams of mass to the chassis. This put the RTR car at 102.2 grams.

Roller pics (not so great, all apologies):

So, next thing was to give it some test runs on the Hillclimb at Fast Eddies in Pinellas Park. This is the same Hillclimb that was in Jacksonville until Ed bought it, and before that was at the raceways in Oldsmar, so it ain’t like I haven’t seen this track before. However, it must be noted my infrequency of getting to the track these days has advanced my typical driving ability from its usual level of mediocrity to something more abysmal. Have to work on that. Fortunately the same crummy driver is used to assess and compare all my cars. If nothing else it’s nice to know this variable can be accounted for.

That said, the 1237-Cc2 ran just as fast as any of my 1229’s tonight, and that was with a mediocre motor. Its handling is predictable, and better overall than I predicted. The adjustable bite bar proved beneficial, especially as the newly cleaned and glued track ran in. It is still not as smooth, forgiving and fast as the 1233-Cc3, my current benchmark, but, considering this is a “basic” chassis by comparison, it bodes well for the “1237” framing pattern to be used for this design/build progression.

And, that said, brings me right back to the original progression of builds I stated at the onset of this post. At this point I will at least need to build the 1237-Cc3, the 1238-Cc3, and 1239-Cc3 into full frames so I have something in my hands to physically observe the dynamics of each chassis and how it compares with the previous (and subsequent) builds. Whether they all get dressed out as RTR cars is still optional, but it is more likely at this time. In other words, I’ve concluded it is best to keep telling myself, “No skipping steps, idiot!”

Consider yourselves forewarned.

Dang, this hobby can be addicting…

Rick / CMF3

Bookmarks