-

1240-Cc3 / Stand Up

Finally, time for the last installment in the opening series of 1237-based designs and builds, the 1240-Cc3.

The 1240 is the 1239 with the addition of “harmonic dampening rails and pans”. Building them in is easy; explaining them is the hard part.

(Warning: Long explanation of why. Those of milder constitutions, or just the easily annoyed may skip to the End Warning…)

In essence, the basic component of any slot car chassis is some structure that holds the guide in conjunction with the drive system (motor, gears, rear axle and tires). This by itself will go around a track. So, when you think about it, everything else, while necessary for a complete slot car, is still adjunct to this basic component structure. Accordingly, on the 1237, 1238, and 1239 the largest and heaviest structural component is the Rear Assembly (motor box, rear axle tube, and flanking static pans) and the Center-Guide section (with the guide mount) that it is directly connected to.

The postulate is that input from the track to the guide and/or rear tires can create vibrations within the basic chassis structure that will adversely affect the overall chassis handling.

The theory is that adding some type of dynamic pans to the chassis will help to counteract any input to the chassis that can cause vibrations in the chassis. In some communications a few years ago, a correspondent referred to this as slot car chassis “harmonics”; sounded kind of all sci-engi-techy cool to me, so I like to call them “harmonic pans”.

How and where these “harmonic pans” are added to a chassis will get you a rather wide variety of ideas and answers. On the 1237’s I just mounted some loosely articulating pans between the Center Main Rail and the Buttress Rails (not an original design element; added as an afterthought since the opportunity presented itself). However, on the 1239 these would have interfered with the Front Axle Rails (FAR’s) and the Indirect Main Rails (IMR’s), so they were omitted (and also not used on the 1238 in recognition of this subsequent required omission).

My own current take on this was first tried on the 1233, which was basically a 1229 with four harmonic pans. I honestly had serious doubts that my light wire structures would have very much effect. I was wrong, as the effect was quite dramatic. Since it had worked so well before, I definitely wanted to try them on a 1237-based chassis.

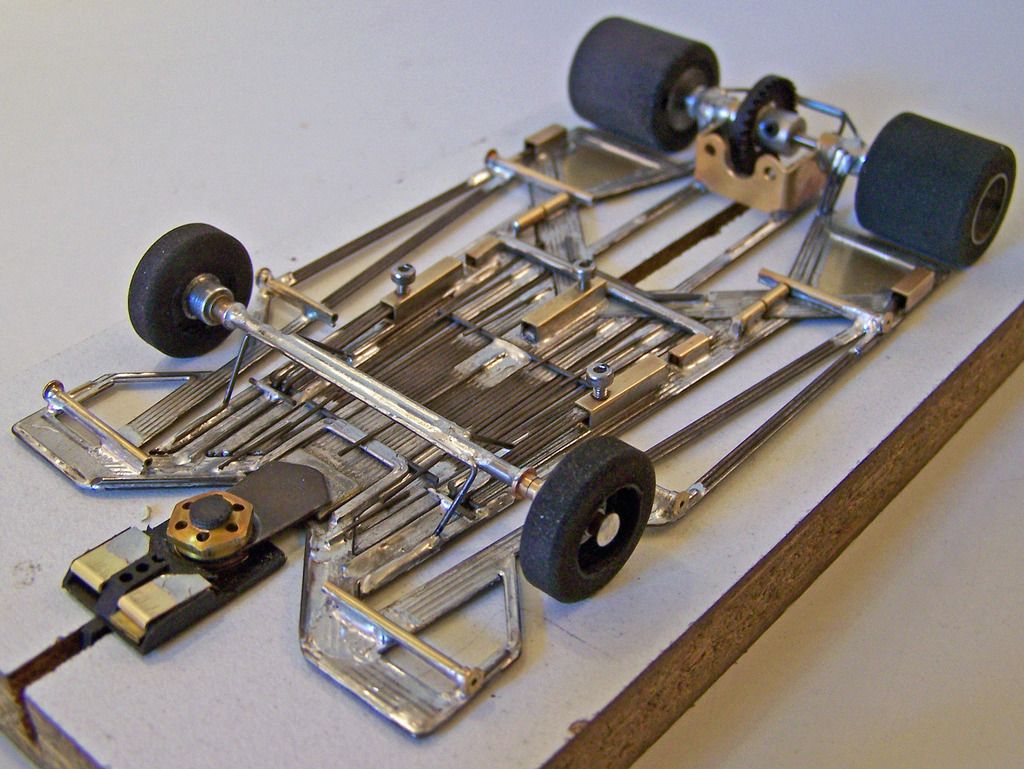

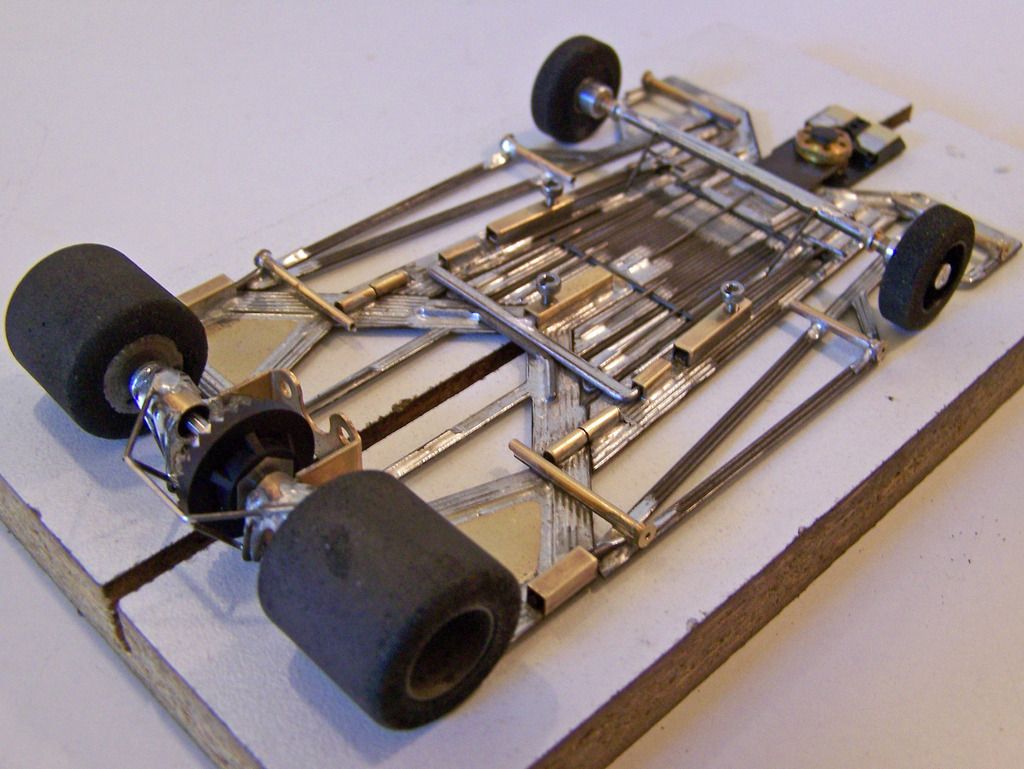

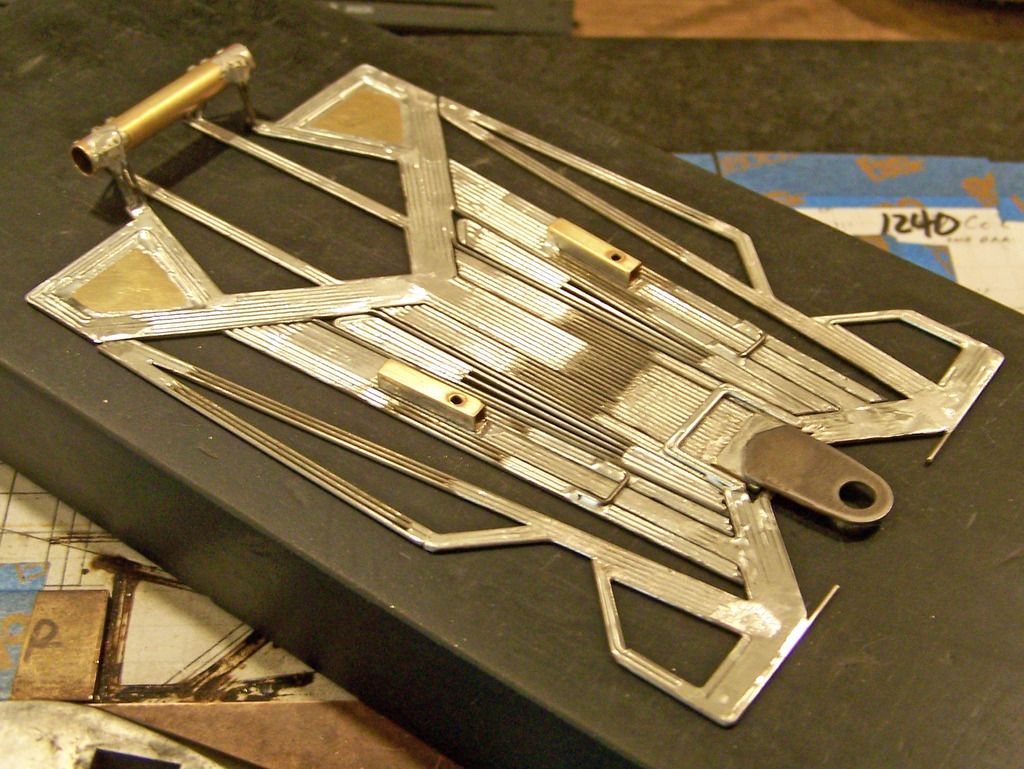

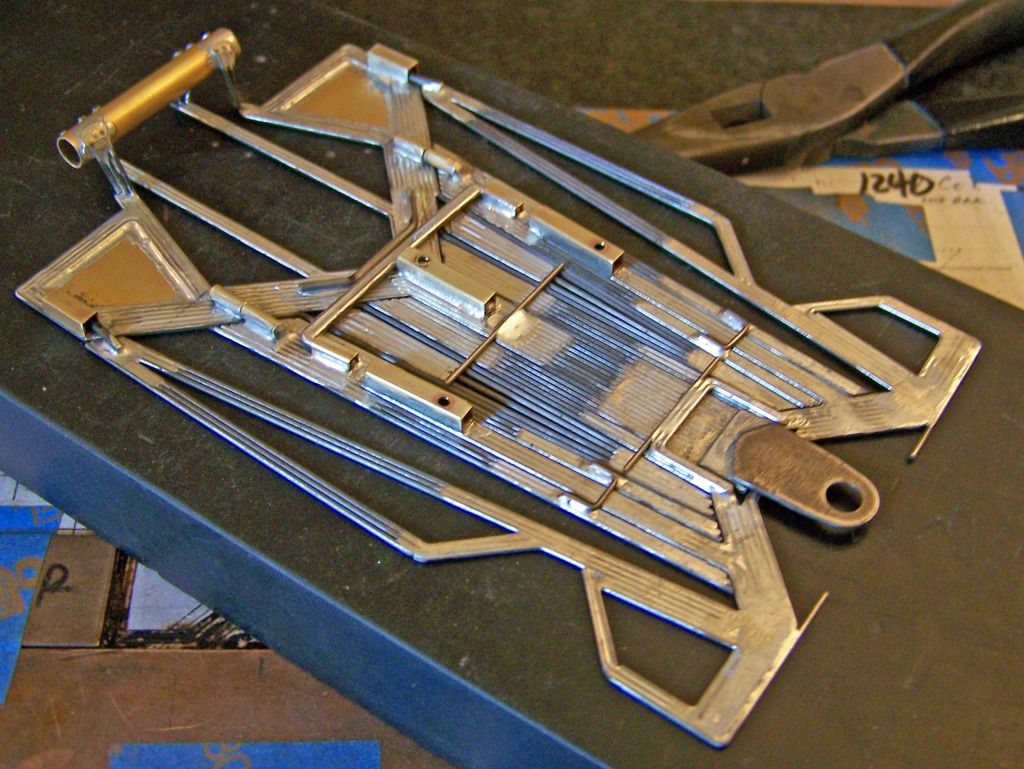

My harmonic dampening system on the 1240 consists of left and right components located between (but not attached to) the IMR’s and the FAR’s (the same general location as the pans on the 1237’s). For each, two rails (Harmonic Pan Rails; HPR’s) are attached only to the Rear Assembly and extend forward as far as possible along the lateral and medial aspects of the IMR-FAR space. A wire “pan” structure (Harmonic Pan; HP) is attached only to the forward portion of the HPR’s, extending rearward to “fill” the IMR-FAR space.

I have a couple of thoroughly hypothetical notions going here. (I’ll be the first to admit I WAG a lot of this stuff…). I want the HPR’s (and HP’s) as long as possible; this allow me to use the least amount of structural mass to get the desired effect. I’ll forego all the reasoning mumbo-jumbo; any poor soul wanting to hear it can ask…

Since it is the “chassis basic structure” (guide-to-drive) I am trying to “dampen”, I have chosen to attach the Harmonic Dampening System to, and only to, the forward aspect of the Rear Assembly, and not to some adjunct component structure. (Keep in mind, my front axle and wheels are already “isolated” from the “basic structure” through the Front Axle Rails via the Buttress rails and the Indirect Main Rails, so any input here is already accounted for.)

Sorry. Go get some aspirin.

(End Warning. Hey, I tried to tell you…)

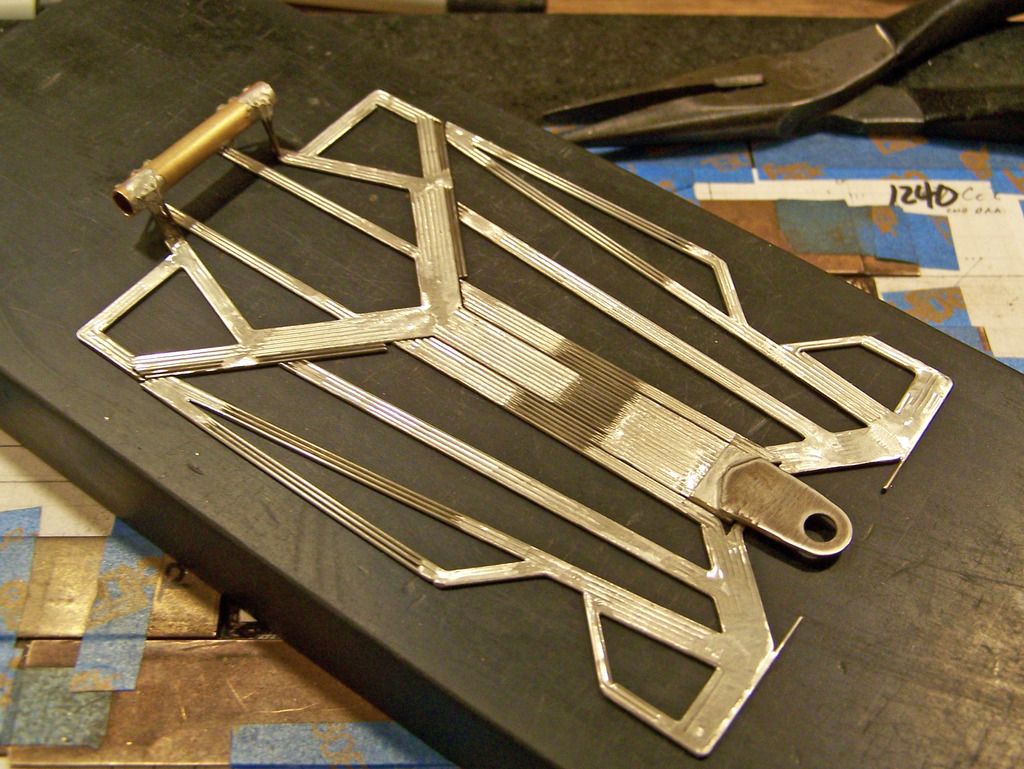

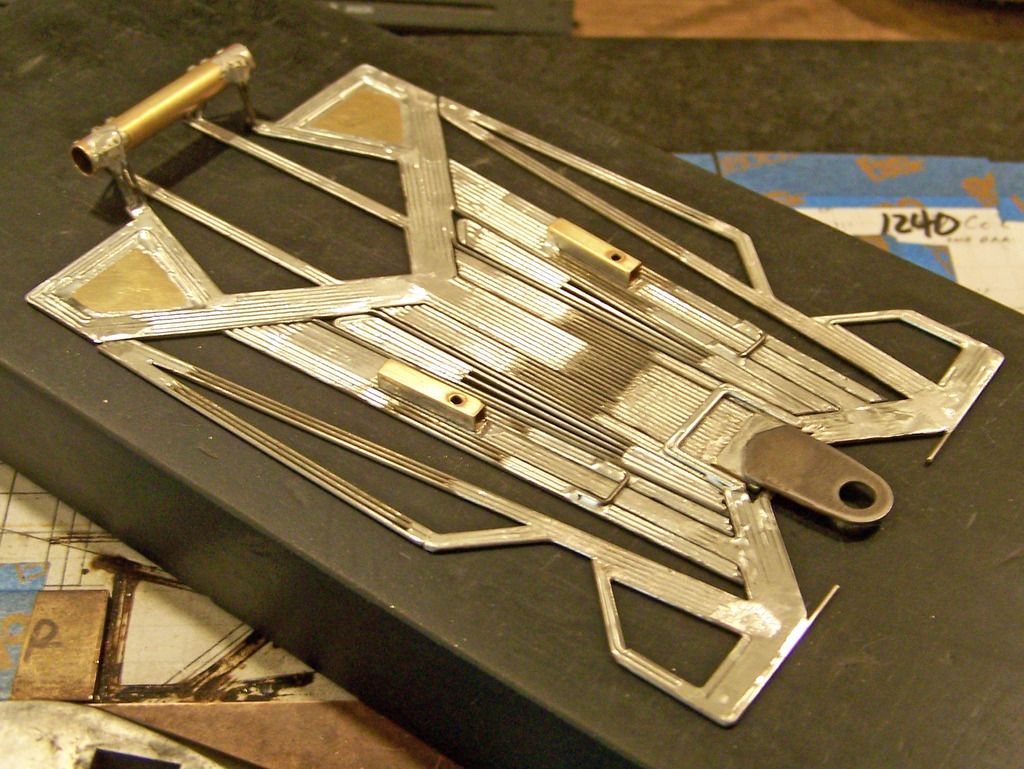

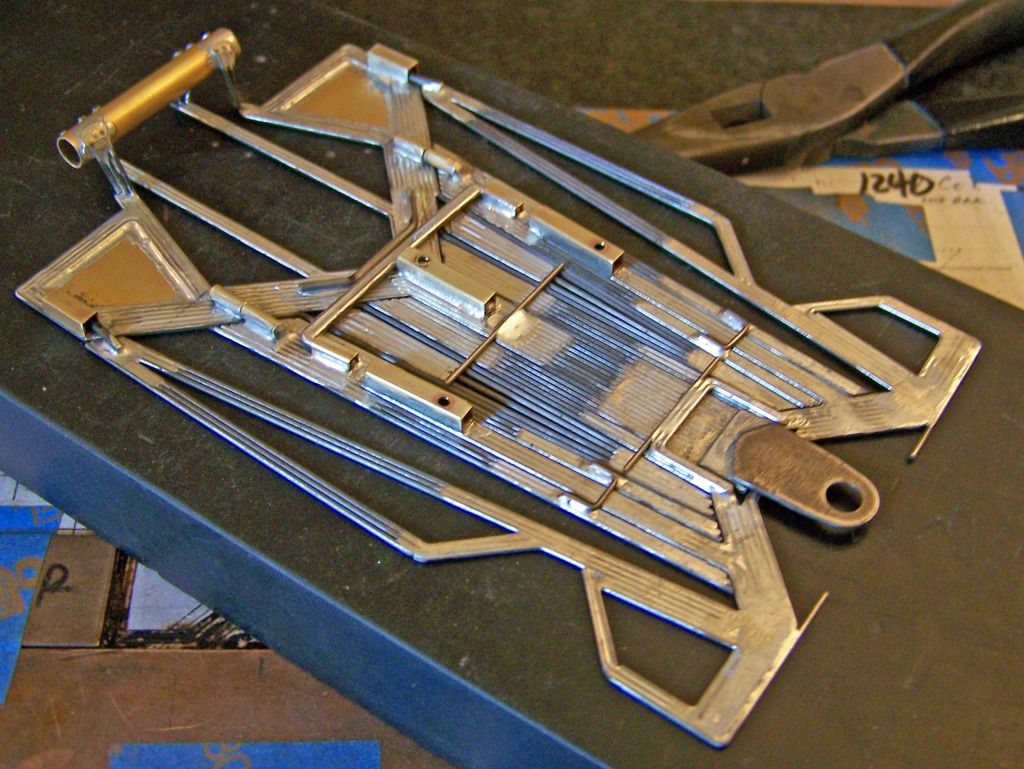

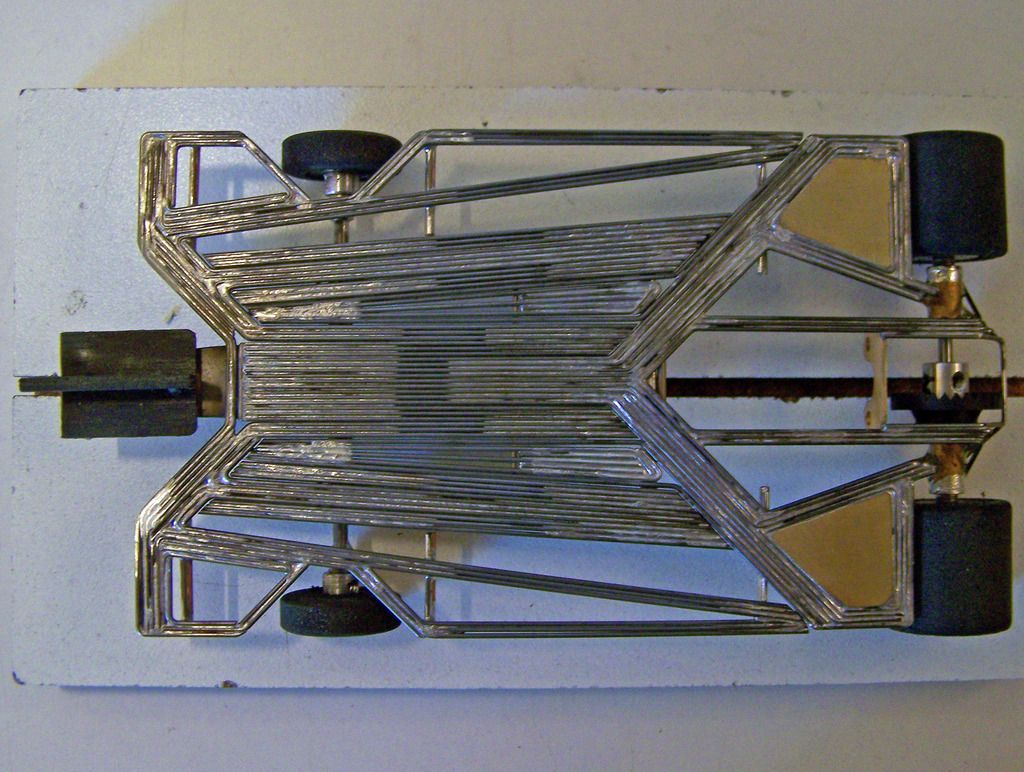

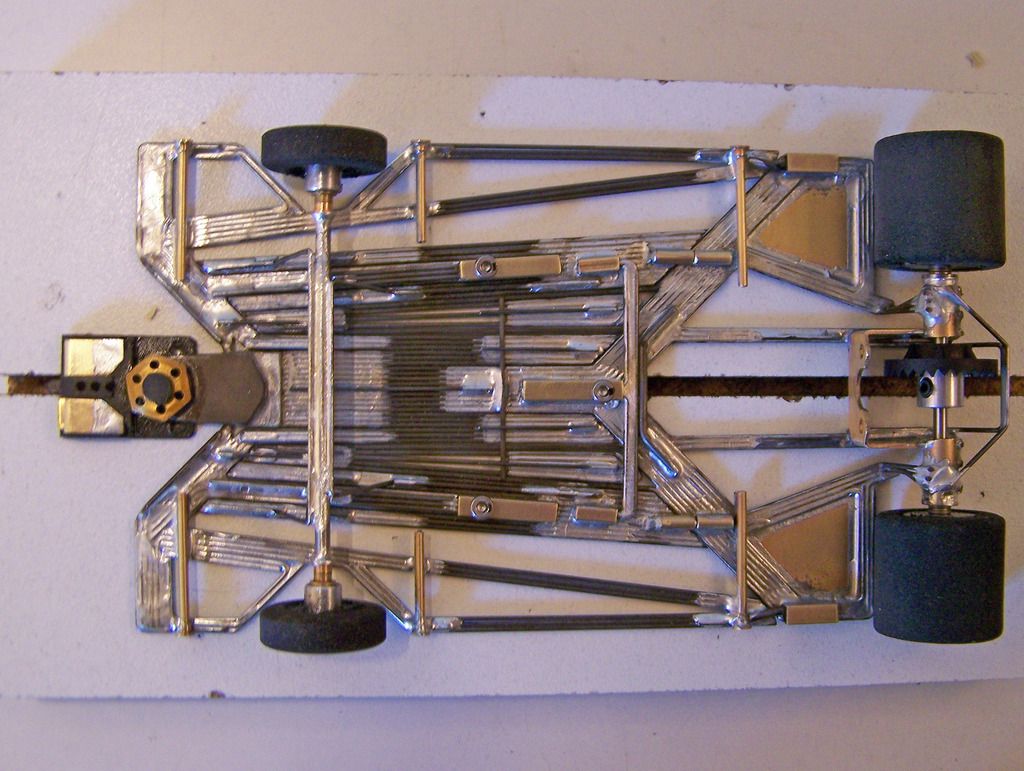

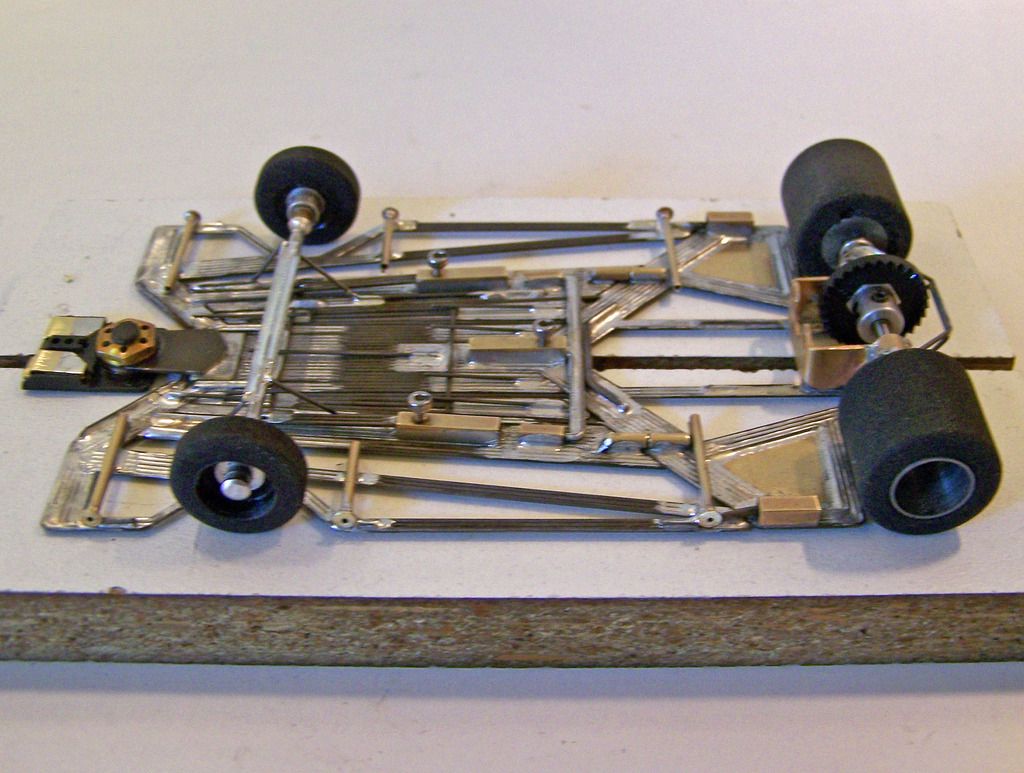

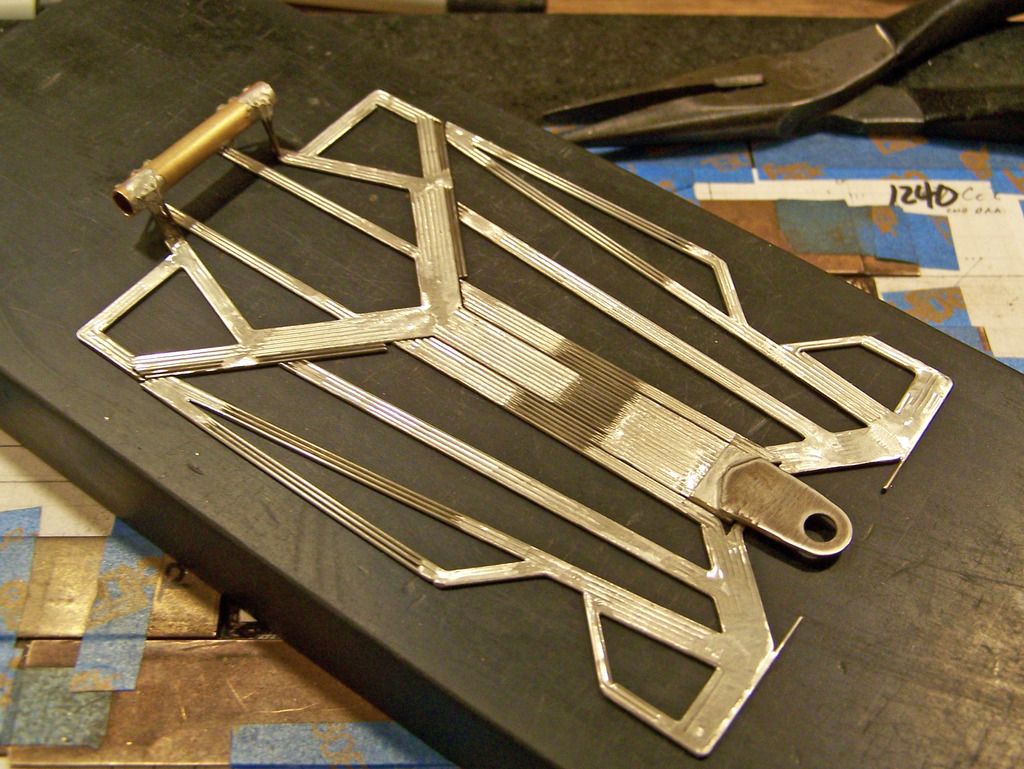

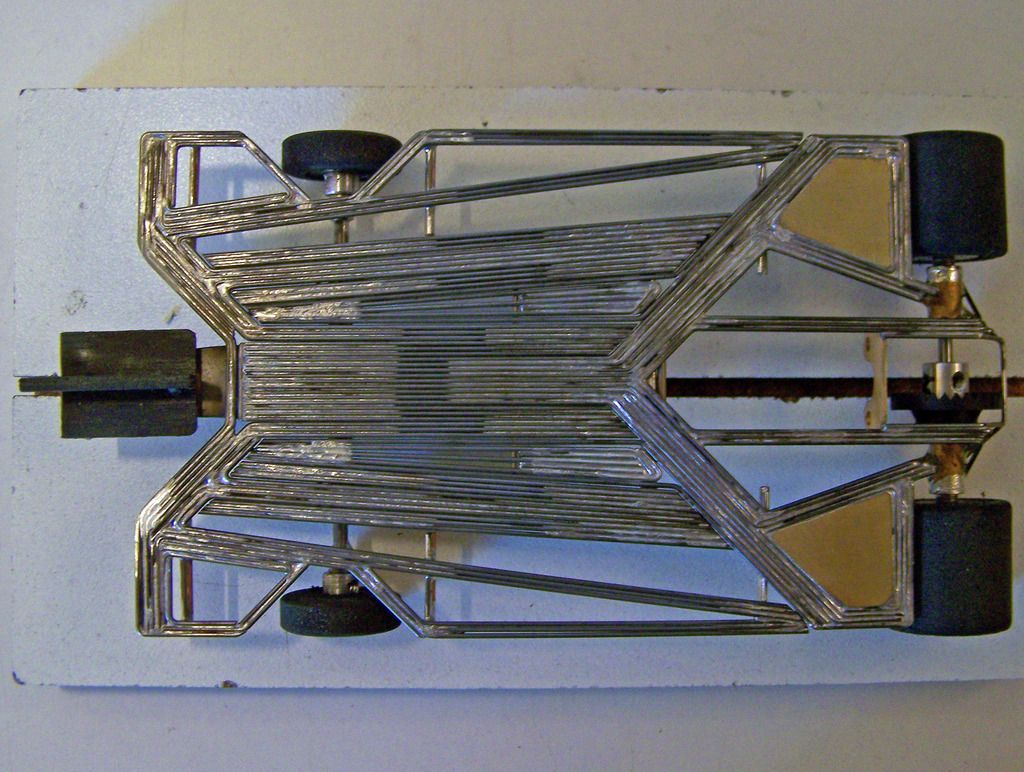

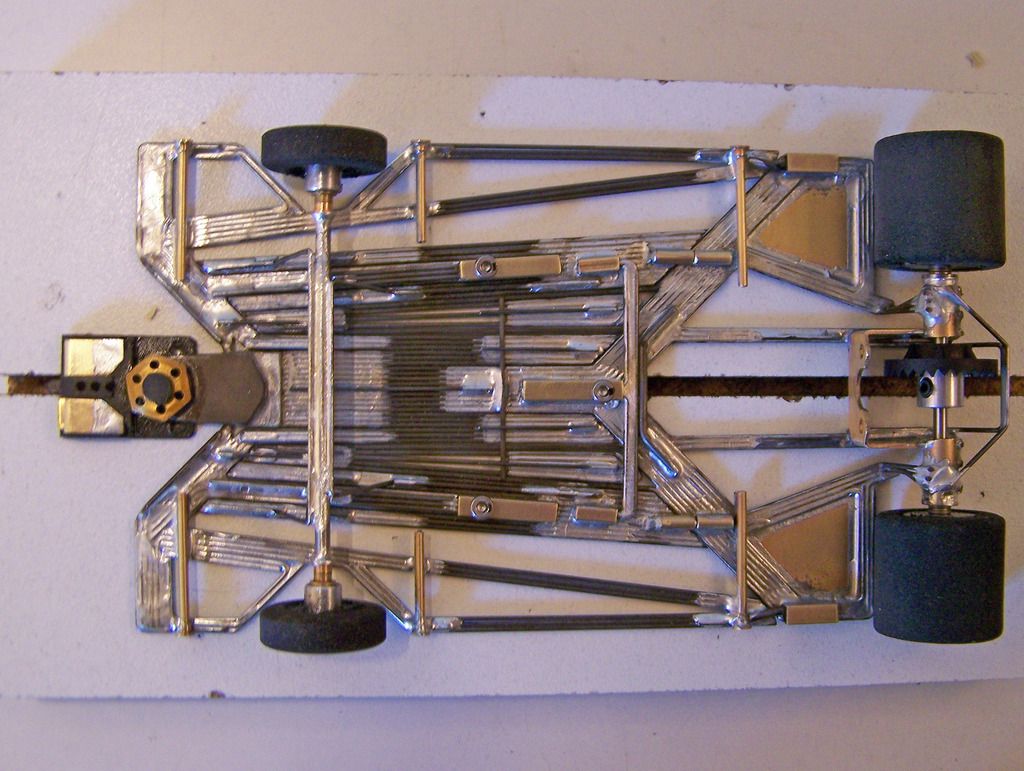

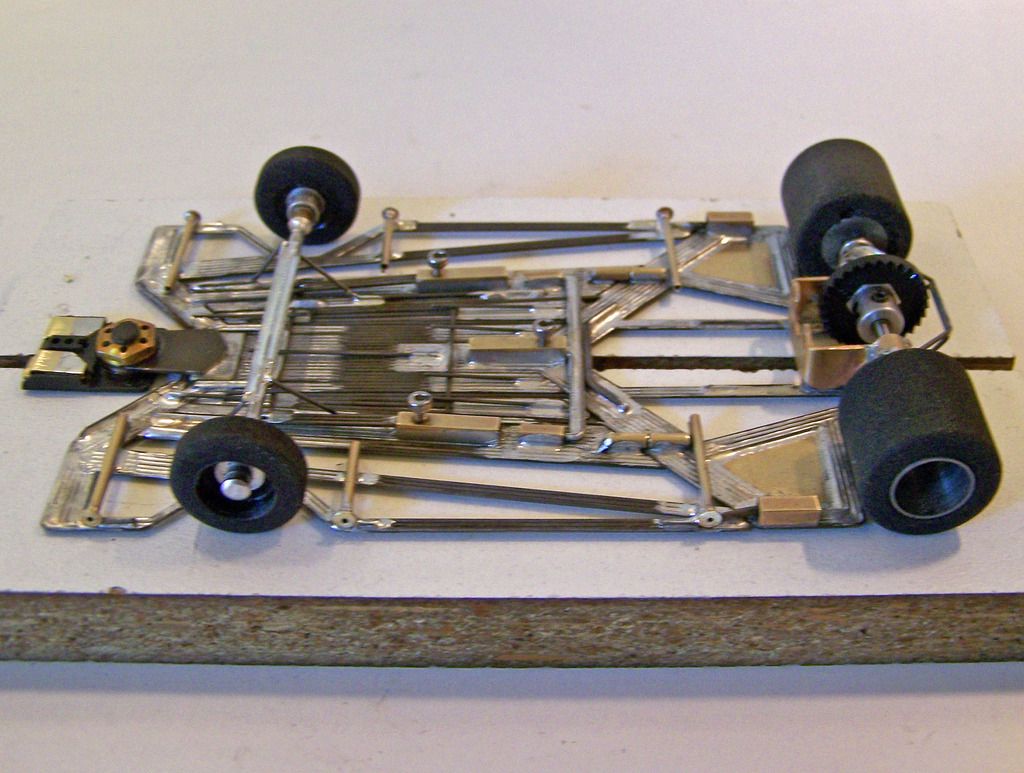

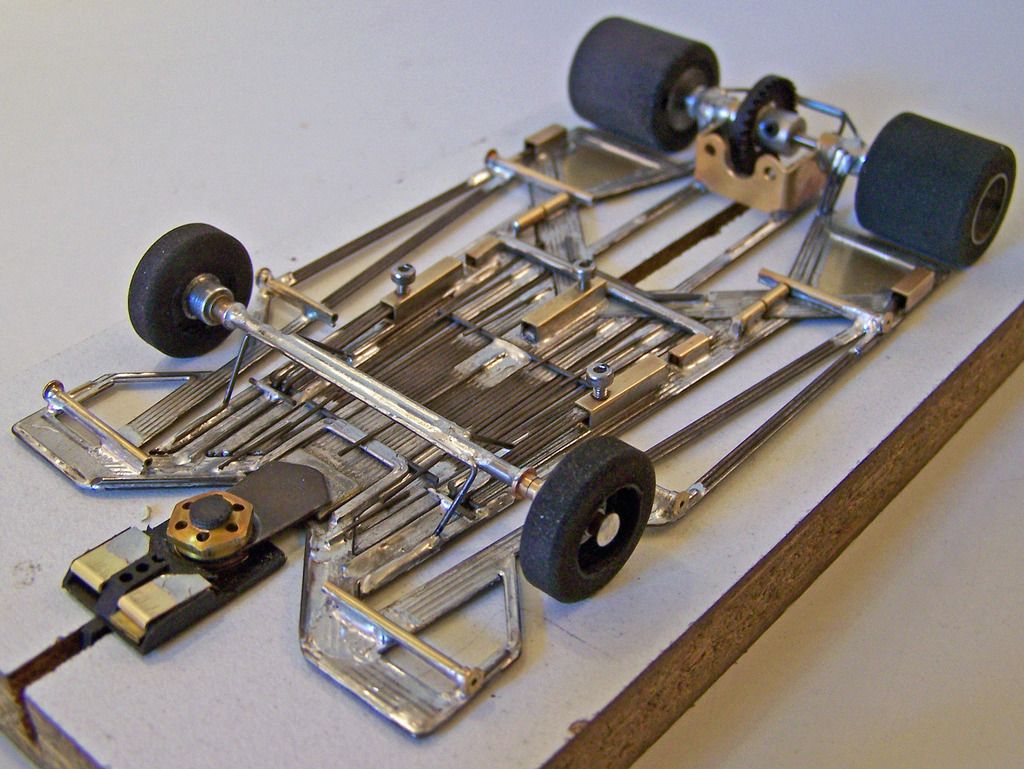

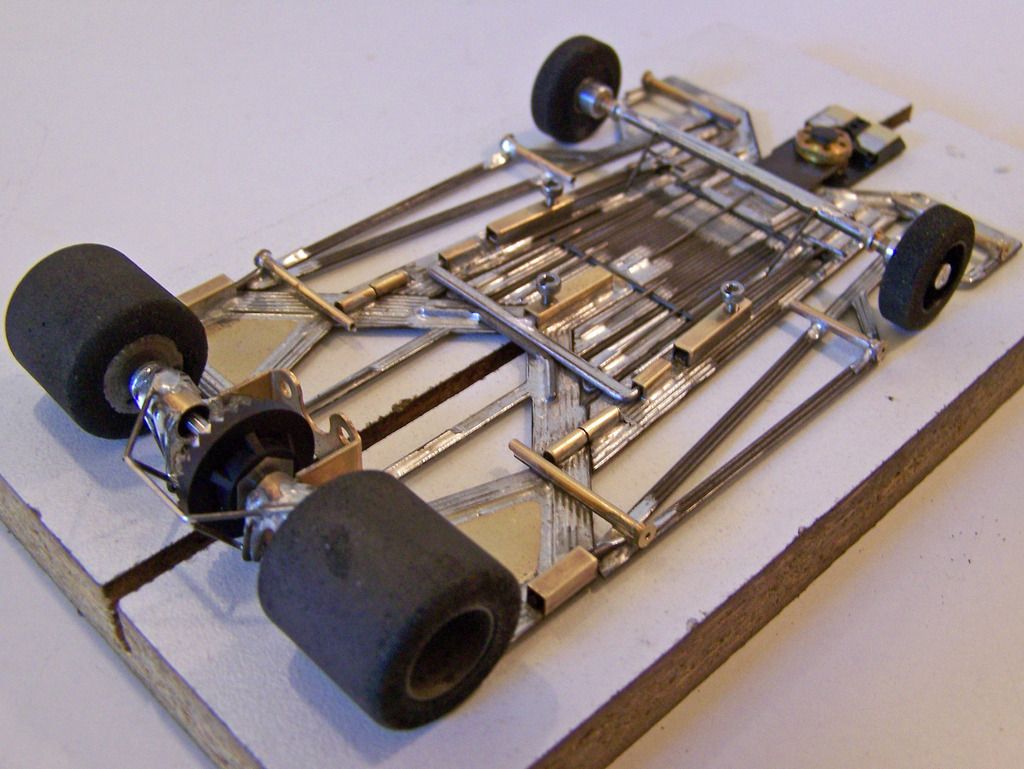

Some pics of the 1240-Cc3; three pics during the build, and the usual roller pics:

(Some of you may want more aspirin… or something stronger…)

The RTR came out to 105.5 grams. So the incorporation of the HPR’s and HP’s added another 4.7 grams over the mass of the 1239-Cc3 (final RTR configuration was 100.8 g). Conceptually and functionally the 1240-Cc3 is the same as the 1219-based 1233-Cc3, which weighs 107.5 grams RTR, but is 2.0 grams lighter. The 1240 is also a lot less cluttered and easier to build than the 1233, even though the 1240 has the adjustable bite bar, and has separate left & right FAR-VSW’s instead of just one. So the 1240 not only weighs less, but has more “shtuff” and weighs less.

The real question is how the 1240 compares to the 1239 and the 1233 on the track.

Initial testing showed the 1240-Cc3 to be as good as the 1239-Cc3. I would describe track conditions as “loose”, but these two cars were much better at handling the track condition than any other chassis, including the 1233-Cc3. And the motor that I put in the 1240, which in test conditions outside of the car seemed comparable, was noticeably lacking compared to the motor in the 1239, but still managed to turn laps equal in general, and only 0.04s off on best lap time.

Not surprisingly, much more testing is needed with these chassis, enough so that it should keep me from building any more retro CanAm chassis for a while…

Of course, this doesn’t rule out any new F1 builds based on the 1237 concept…

And did I mention that at Fast Eddie’s raceway he has a huge tri-oval track? Ran my old Stocker on it last night for fun… You know, I haven’t built a Stocker in about five years…

Oh, and he has a drag strip too. And, I was thinking, I haven’t built any dragsters in more than fifteen years…

So many slot cars, so little time…

Rick

-

Rick,

Your builds and workmanship are amazing!!!

I wish i could build half as neat as you.

I've been a slot car enthusiast for most of my life (started in '63 with an Airfix figure 8 track with Cooper and Ferrari cars).

For my day job i'm a structural engineer so i have some understanding of structures, vibrations and dynamics.

For a "harmonic damper" to work you need to know the frequency of the vibrations that you want to dampen (probably the natural bending ferquency of the chassis) and the frequency of the applied vibrations (probably from track roughness).

Normally the damper is designed to have a natural frequency lower than that of the main structure so that you use up vibrational energy just moving the damper around, the result is the main structure vibrates less as the energy is being used up driving the damper up and down.

The maths is really complicated but a harmonic damper would only be much use at a particular frequency (say from roughness spacing at s particular speed).

This would be very different for different tracks, roughnesses and speeds.

I wonder if what you have very successfully built is a better articulation and mass distribution which should work over a wider range of tracks and speeds.

Not sure myself but keep going your success and determination are winning whatever the physics.

Regards

Ian (irco)

Sent from my SM-N920I using Tapatalk

-

Hey, Ian!

“Not sure myself” is definitely the operating premise in use for my part.

This is why I try to stay within a planned series of builds within a design sequence, so I can actually observe the chassis handling characteristics in relationship within that design sequence... That said, I am the first to also deviate from this logical progression... Picture of an idiot in action...

My original premise was to isolate as many moving components from each other, or at least as many as possible, with regard to the rear tires / drive system / guide component of a slot car chassis. In doing so I tried to decrease the relative mass of any single moving component (relative in as much as the total chassis mass can increase, again relative to another similar design/build). Early on, my own trial and error trended towards non-hinged articulation (the misnomer “torsional” movement), as it seemed relatively little movement was effective. (Admittedly, this also made it easier to continue building the all-wire frames I’ve been playing with for some time now.) In the long run I’ve wound up with chassis that have a range of moving components (mass, length, distance) that possibly work in some relationship to each other, for which I must return to my overall operating premise…

Not sure myself...

Rick

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks